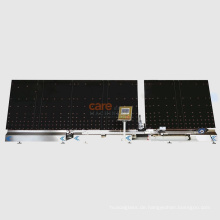

Manufacturer supply laminated float glass cutting machine

Basisinformation

Modell: SZ-LAM33-26

Produktbeschreibung

Manufacturer supply laminated float glass cutting machine

The movable cutting bridge has two functions:

2) The second function is to allow the correct and precise positioning of the laminated glass at the measure that laminate glass need to be cut.

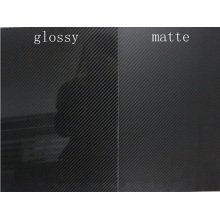

Workable Laminate glass 3+3+0,38PVB to 8+8+4.52PVB

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in case of lack of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head, as soon as an emergency occurs.

Work surface height:

Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Weight Kg. 2400 Maximum installed power Kw 16

Sliding systems

Sliding systems of the bridge are made with a pinion-rack system. The racks and the pinions are tempered and refaced. They have a ± 0.02 mm tolerance with 1.20 mt (47.24 in) length. The teeth racks are turned towards low. One pinion are placed on the two sides of the bridge (two in all), to keep always perpendicular the bridge to the cutting table during the acceleration and deceleration phases.

On Two side of the table is applied one linear guide and one rack, to obtain a overall bridge stability during the cutting cycle.

Arms for load and unload sheet of glass

Loading system with pneumatic cylinder movement, with 2 cylinders with anti-fall safety valves.

This avoids shakes and vibrations of the work surface through the time.

Loading bar have a special new innovative tilting system that is able to loading glass sheet in one time movement, after loading, machine is ready to start cut with laser 3 point research without manual operation.

User interface

On a Multitasking systems, control of three interpolated axles, easy-to-use, with icons and buttons of the relevant command, with Computer WiFi and 21" Touch Screen.

Optimisation program:

Optimization software PerfectCut

Included a 250 parametric shapes library, import/export data.

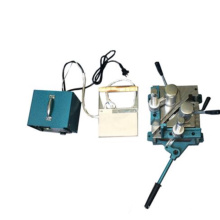

Low-e removal system

The low-e removal happens through a system fixed on cutting head, positioned in front of the cutting system. It deals with a metallic router that allows of remove the coating of the glass both in rectilinear that in shaped. The quality of remove is better than the classical grinding wheel.

The wire brush, which removes the coating,is put in rotation by a Electric motor that running at 20.000 rpm.

Coating must be removed before cutting.

Label Printer on PC cabinet

Professional Label Printer is fixed directly on board of PC cabinet.

That facilitates the work of manual labeling single pieces of glass, since machine operator can print all the labels of the single glass sheet directly from the interface of the cutting table without any confusion and without wait for it from office people.

Film cutting-Vinil for design the patten of sandblasting processing

Separation laminate glass systems (Optional)

New patented system that allows to perform the separation of laminated glass, just taking the glass on the bottom of the glass sheet with the special suction area.With this solution, is possible to handle and cut the glass Low-e without touching the delicate surface of the cooat.The breaking of the glass, after the incision, is made by light flexion, generated by the single tilting of the suction area.

PVB separation through a combined system of medium-fast waves IR light and blade mounted directly on the lower cutting head, to obtain the minimum cycle time, and a clean cut of PVB.

Sager Tec. is a professional designer and manufacturer for machinery, which specialized in glass industry. At initially, Sager was dedicating to design and produce glass laminating equipment and glass cutting machine, as long as providing solution for laminating glass processing.Our business philosophy is “ source integration, technology renovation, ensures quality and service clients” we promise only to what we can achieve. Beijing provide qualified and advanced products for our clients in glass industry is our mission.

1.Question:Are you manufacture?

Answer:

Yes,we are the professional manufacturer for 5 years

2.Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).more than 12 years experience in this kind machine field

3).fluent english ,communication barrier free

3.Question:What’s the guarantee ?

Answer:

1).Our guarantee for 12 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).1 year quality guaranty for the machine

5).24 hours on line service each day, free technical support.

4. Q: Do you provide equipment operation training?

Answer:

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

5.Question:if our price is higher than another company or factories ?

Answer:

please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts, sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous and reliable parts on machine.

6.Question:How long is the delivery time ?

Answer:

30 working days after receipt your deposit

If you are interested in our glass cutting machine, please feel free let me know.

Produktgruppe : Glasschneidemaschine

Premium Related Products