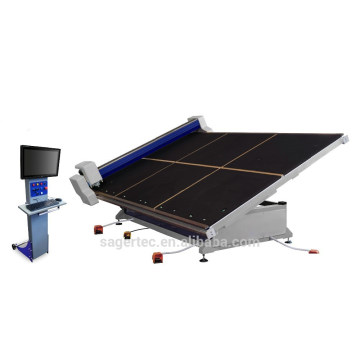

Best Price Glass Cutting Machine China Manufacturer

Basisinformation

Modell: SZ-C3726

Produktbeschreibung

Glasss Cutting Machine

Equipped with:

Control panel with incorporated independent Computer WiFi and 21" Touch Screen , software packet with optimization program developed in Multitasking systems with 250 parametric preconstructed shapes, user graphic interface for the managing of the cutting cycle and machine monitoring , hydraulic tilting surface, air cushion, ventilator for the movement of the sheet on the surface, , double zero for the cutting of laminated glass, security systems following the laws,handbook in English.

Max. workable glass sheet mm. 3700x2600.

Workable thickness From 2 to 19 mm (0.079 to 0.748 in). Machine can cut every kind of glass (except tempered ones)

Safety of the glass presence:

A sensor is placed on the cutting head, to stop the machine in case of lack of glass sheets

Management of mechanisms:

Immediate and controlled braking of the bridge and the cutting head, as soon as an emergency occurs.

Weight Kg. 2200

Work surface height:

Adjstable from 890 to 960 mm (34.65 to 38.19 in)

Maximum installed power Kw 10

Sliding systems:

Sliding systems of the bridge are made with a pinion-rack system. The racks and the pinions are tempered and refaced. They have a ± 0.02 mm tolerance with 1.20 mt (47.24 in) length. The teeth racks are turned towards low. One pinion are placed on the two sides of the bridge (two in all), to keep always perpendicular the bridge to the cutting table during the acceleration and deceleration phases.

On Two side of the table is applied one linear guide and one rack, to obtain a overall bridge stability during the cutting cycle.

Hydraulic tilting systems:

Hydraulic with 2 cylinders with anti-fall safety valves. A valve splits the oil flow up on the hydraulic power cabinet, to guarantee a long duration of the simultaneousness of going up and down of the pistons. This avoids shakes and vibrations of the work surface through the time.

Cutting bridge:

The cutting bridge is made in rigid Steel. The whole system is very stable and insensitive to temperature changes, assuring a minimum wear and tear.

Cut trolley Made in aluminium. The cutting head is made with special machines with hundredth tolerances. Going up and down system of the cutting head is guided by a system with re-circulation of ball-bearings, to reduce the friction as much as possible and guarantee the cutting head reply to glass sinkings.

Glass sheet squaring:

The alignment of glass sheet is automatic trought laser 3Directions.

Work surface Made in very hard wood, covered with woollen felt of high density and compactness, 4 mm thick (0.157 in).

Laser scanning (Optional Included):

Laser System for copying of the shapes, of any material, with double control of the correct survey of the points.

Performance:

Maximum speed of the bridge and cutting head 160 m/min

Max. acceleration 0.8 sec. from 0 to max. speed

Max. deceleration 0.8 sec. From max. speed to 0

Accuracy:

Max. difference in length between two diagonals for an area bigger than 2mq (21.528 sq.ft.) (glass 3 mm thick) (1.118 in.) +/-0.20 mm (0.0196 in)

Rectilinearity tolerance (glass 3 mm thick) (1.118 in.) +/- 0.15 mm (straight cutting) +/-0.20 mm ( shape cutting).

User interface:

On a Multitasking systems, control of three interpolated axles, easy-to-use, with icons and buttons of the relevant command, with Computer WiFi and 21" Touch Screen.

Optimisation program:

Optimization software PerfectCut

Included a 250 parametric shapes library, import/export data.

Low-e removal system (Optional):

The low-e removal happens through a system fixed on cutting head, positioned in front of the cutting system. It deals with a metallic router that allows of remove the coating of the glass both in rectilinear that in shaped. The quality of remove is better than the classical grinding wheel.

The wire brush, which removes the coating,is put in rotation by a Electric motor that running at 20.000 rpm.

Coating must be removed before cutting.

Glass film cutting(carving) function

Exhibition

Factory

Established in 2008, Sager Tech.is a professional designer and manufacturer for machinery, which isspecialized in glass industry. We are located in Beijing, with convenient transportation access. All of our machine comply with CE regulation and are greatly appreciated in a variety of different markets all over the world.

At initially, Sager was devoted to design and produce glass laminating equipment as long as provide the solution to work for laminating glass. With a fast development, Sager was starting up the project for new glass processing machine by optimized cooperation and source integration. Now, our products range is increased, which include completed PVBEVA laminating production line, laminating furnace and material, all the type of grinding machine, washing machine, drilling machine as well as sandblasting machine.

As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching USA, Europe, Australia, South America etc.

Our business philosophy is TECHNOLOGY RENOVATION, COST CONTAINMENT, QUALITY CONTROL and SATISFACTORY AFTERSALE SERVICE. Being provide qualified and advanced products for our clients in glass industry is our mission.

Produktgruppe : Glasschneidemaschine

Premium Related Products